Hydrodynamics and transport processes

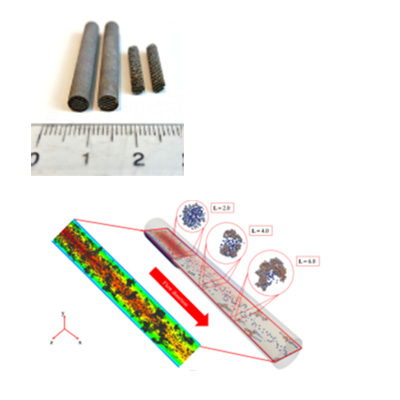

We have developed experimental and theoretical approaches to characterize single and two-phase flow hydrodynamics and transport processes in small-scale flow reactors. These developed tools are applicable to different length scales, and therefore enable a fundamental understanding of the scalability of transport coefficients and the underlying transport limitations. Furthermore, the developed theoretical models capture a wide range of (multi)physics phenomena, including improved CFD models for multiphase flows (fluid-fluid or solid-fluid), and complex kinetic reactor models.

Example references

Cailly, W., Mc Carogher, K., Bolze, H., Yin, J. & Kuhn, S. (2023) Analysis of Dynamic Acoustic Resonance Effects in a Sonicated Gas-Liquid Flow Microreactor. Ultrason. Sonochem. 93, 106300.

https://doi.org/10.1017/jfm.2023.968

Yin, J. & Kuhn, S. (2022) Numerical simulation of droplet formation in a microfluidic T-junction using a dynamic contact angle model. Chem. Eng. Sci. 261, 117874.

https://doi.org/10.1016/j.ces.2022.117874

Ferreira, J., Castro, F., Rocha, F. & Kuhn, S. (2018) Protein crystallization in a droplet-based microfluidic device: Hydrodynamic analysis and study of the phase behaviour. Chem. Eng. Sci. 191, 232–244.

https://doi.org/10.1016/j.ces.2018.06.066

Potdar, A., Protasova, L.N., Thomassen, L. & Kuhn, S. (2017) Designed porous milli-scale reactors with enhanced interfacial mass transfer in two-phase flows. React. Chem. Eng. 2, 137–148.

https://doi.org/10.1039/C6RE00185H

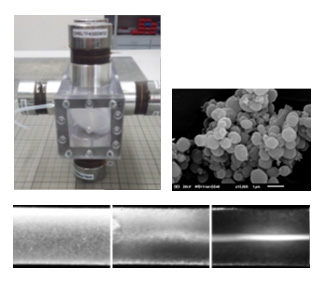

Crystallization and controlled particle synthesis

We have developed experimental and theoretical approaches to characterize single and two-phase flow hydrodynamics and transport processes in small-scale flow reactors. These developed tools are applicable to different length scales, and therefore enable a fundamental understanding of the scalability of transport coefficients and the underlying transport limitations. Furthermore, the developed theoretical models capture a wide range of (multi)physics phenomena, including improved CFD models for multiphase flows (fluid-fluid or solid-fluid), and complex kinetic reactor models.

Example references

Brozzi, E., Dusselier, M. & Kuhn, S. (2025) Unraveling the role of ultrasound in hydrothermal interzeolite conversion using a tubular ultrasound-integrated reactor. React. Chem. Eng. 10, 2311–2320.

https://doi.org/10.1039/D5RE00149H

Udepurkar, A., Mampaey, L., Clasen, C., Sebastian, V. & Kuhn, S. (2024) Microfluidic synthesis of PLGA nanoparticles enabled by an ultrasonic microreactor. React. Chem. Eng. 9, 2208–2217.

https://doi.org/10.1039/D4RE00107A

Devos, C., Xiouras, C., Van Gerven, T. & Kuhn, S. (2024) Unraveling the role of fluid shear on primary nucleation of paracetamol through an energy dissipation rate analysis. Cryst. Growth Des. 24, 2713–2723.

https://doi.org/10.1021/acs.cgd.3c01198

Fatemi, N., Devos, C., Van Gerven, T. & Kuhn, S. (2022) Continuous crystallization of paracetamol exploiting gas-liquid flow in modular nucleation and growth stages. Chem. Eng. Sci. 248, 117095.

https://doi.org/10.1016/j.ces.2021.117095

Dong, Z., Udepurkar, A. & Kuhn, S. (2020) Synergistic effects of the alternating application of low and high frequency ultrasound for particle synthesis in microreactors. Ultrason. Sonochem. 60, 104800.

https://doi.org/10.3390/ma13020344

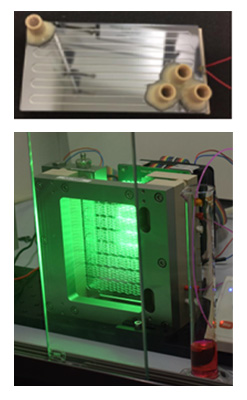

(Micro) reaction engineering for sustainable chemistry

We use our fundamental hydrodynamic and transport process understanding to engineer intensified small-scale reactors for flow chemistry applications. We have developed novel 3D printed porous reactors rationally designed via simulation and experiment, which we apply to liquid-liquid reactions relevant to the fine chemical industry. We also engineer continuous reactors utilizing non-traditional activation modes for chemical transformations (photo- and electrochemistry).

Example references

Kaya-Özkiper, K., Mc Carogher, K., Roibu, A. & Kuhn, S. (2023) Photo-oxidation in Three-phase Flow with Continuous Photosensitizer Recycling. ACS Sustain. Chem. Eng. 11, 9761–9772.

https://doi.org/10.1021/acssuschemeng.3c01869

Zhang, S., Junkers, T. & Kuhn, S. (2022) Continuous-Flow Self-Supported seATRP Using a Sonicated Microreactor. Chem. Sci. 13, 12326 –12331.

https://doi.org/10.1039/D2SC03608H

Roibu, A., Van Gerven, T. & Kuhn, S. (2020) Photon Transport and Hydrodynamics in Gas-Liquid Flows. Part 1: Characterization of Taylor Flow in a Photo Microreactor. ChemPhotoChem 4, 5181-5192.

https://doi.org/10.1002/cptc.202000065

Roibu, A., Horn, C., Van Gerven, T. & Kuhn, S. (2020) Photon Transport and Hydrodynamics in Gas-Liquid Flows. Part 2: Characterization of Bubbly Flow in an Advanced-Flow Reactor. ChemPhotoChem 4, 5193-5200.

https://doi.org/10.1002/cptc.202000066

Potdar, A., Thomassen, L. & Kuhn, S. (2019) Scalability of 3D printed structured porous milli-scale reactors. Chem. Eng. J. 363, 337–348.

https://doi.org/10.1002/cite.201800128